Uncategorized

Flow Testing 6.0L Power Stroke Heads

Will has been having fun testing 6.0L Power Stroke heads on our flow bench. This time, Will is testing our new Power Driven Diesel Stage 1 CNC Ported Cylinder Head. This is a new port design that Will is testing against OEM heads. Read on to see the results of our testing and find out if you need a ported head on your Power Stroke.

Why do you need a ported head on your 6.0L Power Stroke?

The primary reason to upgrade to a ported head is to improve flow through the engine. The stock Ford exhaust valve is only 1.1” versus its 1.34” intake valve. This difference in valve size causes the exhaust flow to be constricted, resulting in a restriction of the entire engine – like running a marathon, but only being able to exhale through a straw when you breathe. It is inefficient and reduces overall engine performance.

Our Stage 1 Ported Cylinder Head opens up the exhaust valve ports to improve exhaust flow through the engine.

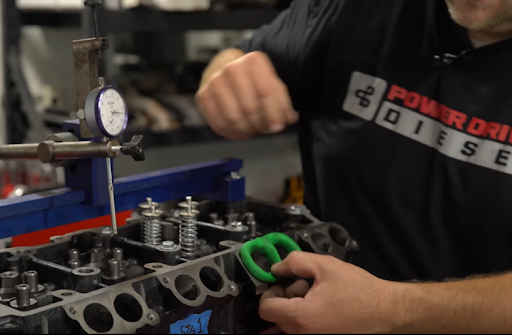

Power Stroke head testing setup

For the test of our ported cylinder head, we attached it to a Bryzinski slider with a factory 3.75 bore size on the flow bench. This allows us to test flow on the same bore size as the factory 6.0L Ford diesel.

We also make sure to plug all the holes, add an exhaust manifold, and more to make sure we are getting an accurate, real world reading with no leaks or cheats to fudge the numbers.

Stock OEM Power Stroke head test results

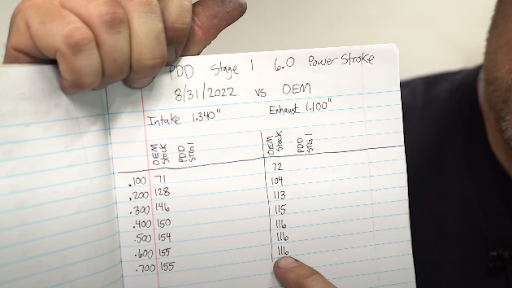

Off camera, we tested a few stock 6.0L Power Stroke heads to establish a baseline. In this test, we incrementally tested different lift heights to see where flow peaks. We even push above what is feasible to run in the real world.

In our stock test we saw intake peak at 155cfm at .600 lift. Above that, the numbers plateaued. Stock exhaust plateaued at .400 lift with minimal gains at any higher lift settings. The difference in intake and exhaust flow numbers highlight how restrictive the exhaust side of the engine is, flowing 26% less than the intake side.

6.0L Power Stroke CNC Ported Cylinder Head flow test

Because the Ford Power Stroke doesn’t lift the valve very high, we want to see big increases at low lift numbers. Flow improvements at low lift will improve spool up, torque when starting, and more. However, we want to make sure the flow is stable at higher lifts because that tells us if the engine is going to get choked out because of a bad port, or if the flow will continue to perform.

In this test, we see that where the stock head has plateaued and flow is restricted at .400 lift, the ported head is still increasing flow rates.

|

Intake: 1.345” |

Exhaust: 1.1” |

||||||

|

Lift Height |

OEM Stock | PDD | Difference | OEM Stock | PDD | Difference | |

|

.100 |

71 | 86 | 15 | 72 | 72 | 0 | |

|

.200 |

128 | 148 | 20 | 104 | 111 |

7 |

|

|

.300 |

146 | 188 | 42 | 113 | 138 |

25 |

|

|

.400 |

150 | 195 | 45 | 115 | 147 |

32 |

|

|

.500 |

154 | 200 | 56 | 116 | 151 |

35 |

|

|

.600 |

155 | 205 | 50 | 116 | 154 |

38 |

|

| .700 |

155 |

208 |

53 | 116 | 157 |

41 |

|

Power Stroke cylinder head test conclusion

So, what do we learn from this test? The small exhaust port size on a stock head leads to restrictions in engine flow, ultimately leading to less power and lower performance. A ported head eliminates the choke point in the exhaust port, increasing flow and unlocking power potential. Pick one of these heads and any other 6.0L parts you need today.

If you have questions about which cylinder head and parts are best for your 6.0L Power Stroke diesel, give us a call at 435-962-9555 or text us at 435-962-9506 or leave us a comment below. Don’t forget to follow us on YouTube, Facebook, and Instagram for more product tests. Leave us a comment below about what you’d like us to cover next.